Foot baths have become a staple in wellness routines. They offer a soothing experience and potential detoxification benefits. But have you ever wondered how they are made? Manufacturing quality foot baths requires precision, innovation, and a commitment to excellence. Visit vitalaxion.com to learn more about innovative approaches in this field.

The Initial Design Process

Every great product starts with a solid design. Foot bath manufacturers begin by understanding user needs. This includes analyzing trends, customer feedback, and ergonomic considerations.

Engineers and designers work together to create prototypes. These prototypes focus on usability, safety, and effectiveness. Key features such as ionization technology and temperature control are integrated during this phase.

Material Selection: A Critical Step

The choice of materials is vital for durability and functionality. Manufacturers often use high-grade plastics, metals, and electronic components. These materials must withstand water exposure and maintain electrical safety.

Regulatory compliance is another factor. Trusted brands adhere to strict industry standards to ensure product safety. This includes using non-toxic materials that are environmentally friendly.

Advanced Manufacturing Techniques

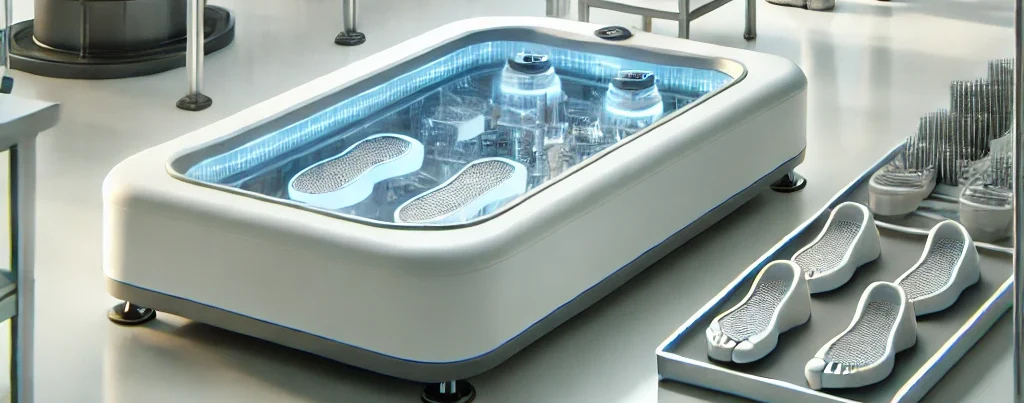

Once the design is finalized, production begins. Advanced techniques like injection molding create the bath’s structural components. This ensures uniformity and minimizes defects.

Precision assembly is crucial. Skilled technicians install ion generators, control panels, and other components. These parts are then tested for proper functionality.

Automation plays a big role in modern factories. Robotic arms and automated systems enhance efficiency. However, quality checks by human experts remain an essential part of the process.

Quality Assurance: The Final Touch

Quality assurance ensures the end product meets high standards. Every foot bath undergoes rigorous testing. This includes electrical safety tests, water resistance checks, and performance evaluations.

Manufacturers also simulate real-world usage. This helps identify any potential issues before products reach customers. Reliable brands maintain transparency by sharing testing protocols and certifications.

What Sets Quality Brands Apart?

Not all manufacturers are created equal. Top brands invest heavily in research and development. They continuously improve their designs and integrate cutting-edge technology.

Customer service also plays a role. Companies that prioritize user satisfaction often include warranties and responsive support. This builds trust and encourages long-term loyalty.

Ethical practices are another differentiator. Sustainable manufacturing processes and fair labor policies set leading brands apart. Consumers today value these efforts, making them an essential factor.

The Future of Foot Bath Manufacturing

Innovation continues to drive the industry forward. Manufacturers are exploring smart technology integrations. Features like app controls and real-time health monitoring may become standard.

As demand grows, sustainable practices will gain more importance. Brands that align with eco-conscious values will likely lead the market. By prioritizing quality, safety, and innovation, the future of foot bath manufacturing looks bright.